|

Model | CA12 cnc cutting machine |

Working Table Dimension | 1220x2440 mm |

X Y Z Working Area | 3150*1780*300 mm |

Workpiece Height | 80 mm |

Max Moving Speed | X axis :60m/min Y axis: 60m/min Z axis: 20m/min |

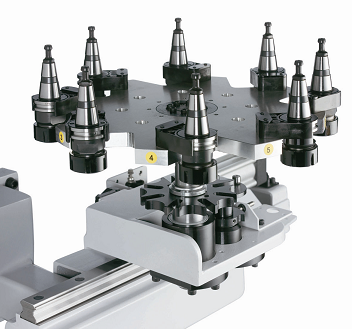

Spindle Type | Auto changing spindle |

Spindle speed | 3000 – 24000 RPM |

Vacuum Area | four vacuum areas |

Spindle Power | 1X9KW Chinese brand |

Vacuum Pumping Power | 10HP(7.5KW)-250m 3 /h |

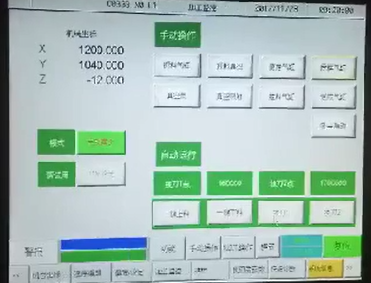

CNC Controller | Syntec control system |

Servo motor | Syntec |

Linear guide | RSK |

Rack | Germany Herion |

Standard Configuration | Toolbox, equipment operation manual |

Dust collector diameter | 8 inch |

Tool System | 1 set |

Machine Over Size | 3700*2650*2300 mm |

Weight | 2200 KG |

1)The automatic tool exchange system can be controlled by the computer for 8/12/24 pcs tool storage capacity, and each type of compound cutter shaft can be automatically changed with the tool library. |  |

2) In the cold weather morning, the users of drill package can click the heat button when start machine, then machine will automatically run the spindle and the drill package heat machine program, which will make the drill package’s drill pipe uniform lubrication to improve the life of drill package。 |  |

3) Tool change The Equipment built-in tool change program, then user just need click the quick button can change the tool, the operator does not need to move the X axis, Z axis, the spindle dropping and other complex operations, quick and eas. |  |

4) No need to return to the origin position One-button start then direct processing without returning to the origin, it can ensure the accuracy, and save processing time, improve work efficiency.

|  |

5) Print labels synchronously In the production workshop, Synchronizing printing labels at the same time , without take the label from the office, without having to search from a pile of printed labels inside, to avoid being wrongly labeled due to worker's sense of responsibility. |  |

| High rigidity structure design, and the material stress analysis and tempering, insure machine’s accuracy non deformation |

| Use Taiwan PMI precision ball screw and CSK guider, Germany Herion rack, with high-speed displacement positioning accuracy, and transmission low noise. Max moving speed up to 60 M / min, and moving smooth and accurate . Then max processing speed up to 30 m/ min. |

| All electronic component adopted European standard (CE certified) components, such as South Korea LS, France Schneider. |

cnc cutting machine manufacturing

|  |

| |

1. Payment Terms & Conditions

1) Payment term: By T/T, 30% advanced payment at order confirmation, 70% balance before delivery. (Customized order payment term: 50% deposit after order confirmation, and 50% balance before delivery).

2) One year warranty for whole machine, and lifelong service responsibility.

3) Delivery date: 30 working days after receipt of deposit

4) Quotation validity: 30 days

|  |

If you have any requirement or question, please fill out the form below that we will reply you within 24 hours.