|

How Beam Panel Saw solves diagonal error problems

Within the daily operation with the Beam Panel Saw, we must not merely be aware of operating specifications and technical characteristics of the electronic cutting saw, and also understand its functional role.

|

1, Beam Panel Saw combined with practical applications, low-cost rapid launch.

Based on fully with the actual situation in the factory, with the special numerical control interface, the seamless eating habits study your computer and the Beam Panel Saw is realized, and the previously backward manual cutting mode is changed into the automated command operation of the machine, as well as the transformation process is not hard and fast. With a low transformation cost, it is possible to completely strengthen your factory opening process and like the high efficiency of technical complexity.

2, Beam Panel Saw no requirement to professional host, reduce labor costs.

Prior to transformation, the manual cutting plan calculation, command input as well as other key links are inseparable from the skilled host. You need to pay more than 4,000 yuan a month for the mainframe salary; the important thing elements of the information transformation as soon as the transformation realize laptop computer automation operation. The outlet process is not hard and convenient, and a normal job using a monthly wages of 1,500 yuan may be qualified for the task from the host.

3, Beam Panel Saw refined discharge, make best use of garbage.

Ahead of the transformation, for the reason that quantity and size the information were completely calculated through the mind, it turned out considered that larger than fifteen was hard to avoid. The grade of the cutting plan depends on the proficiency and professional level with the workers. The garbage will often be not fully utilized and a large amount of expectations are generated. Rarely reclaimed surplus materials, causing great waste; following your transformation, the equipment calculates the information discharge want to achieve the optimal material discharge, and later on uses bar code technology to monitor and manage the remainder materials. When the program is used to provide priority towards the last material. Calculations have led to a tremendous increase in raw material utilization.

4, Beam Panel Saw particles automatic operation, processing efficiency is greatly improved.

The manual operation ahead of the transformation must calculate the complicated discharge plan, and repeatedly input the cutting data as well as the cutting instruction. It will take considerable time along with the work efficiency is low. Following your transformation, the pc as well as the electronic cutting saw are realized. Sewing connection, through intelligent control software, the release plan's directly generated by software, and the cutting parameters are directly transmitted to the electronic saw, and also the production efficiency will likely be revolutionized.

5, you should not manually input, your machine automatically command, in order to avoid errors.

The manual cutting process prior to transformation obviously received the influence from the quality factors, work attitude and status in the workers, and also the error rate remained high, leading to huge waste. After the transformation, the operation of computer automatic command was freed. The subjective dependence of workers greatly raises the accuracy of processing and reduces the error rate.

|

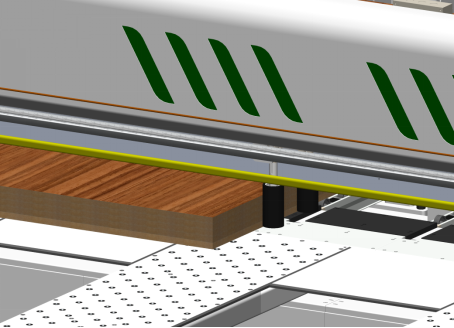

Beam Panel Saw use method

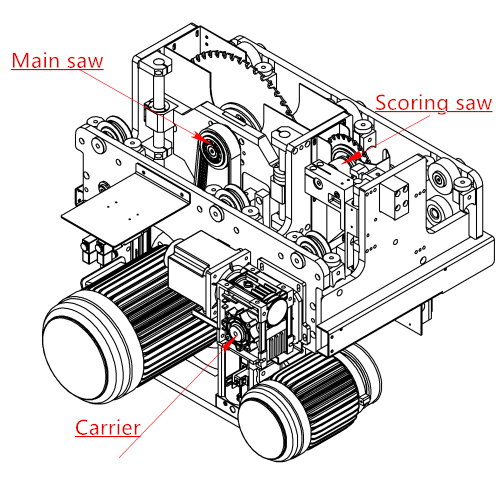

Once the material saw is automatically operated, the feeding robot is first transferred to the set discharge area, the saw blade is moved to the original position, the saw blade is started, and then the plate is pushed to the robot from the ruler, therefore the automatic cycle is started; the robot is clamped. The sheet is pulled backwards, moved backwards towards the international calls in the board, then fed forward based on the set length; following the feeding is done, pressure to succeed beam is pressed down, along with the saw blade is raised; pressure to succeed beam is pressed down and also the saw blade is raised in place, as well as the saw blade advances. Advancing into position, the saw blade descends along with the pressure beam rises. As soon as the position is reached, the saw blade retreats. Concurrently, the above-mentioned action cycle is repeated for the next feeding, until all the set numbers are sawed, the robot runs to the zero position to push the remaining material, and completes a cycle work. .

It demands the automatic control and automatic power over the movement control of the feeding manipulator, the pressure beam, the saw blade as well as the backing plate, and other parameters for example the size and weight with the material.