Precision Sliding Panel Saw Security uses Knowledge

|

|  |

Sliding Panel Saw can be used for longitudinal cutting and cross-cutting of various kinds of wood-based panels such as veneer particle board, fiberboard, plywood and solid wood board, plastic board, aluminum alloy, etc. It is widely used in wood processing industry such as panel furniture industry and vehicle and ship manufacturing, belonging to woodworking machinery. Among the general-purpose equipments, the market demand is relatively large.

With the large-scale application of wood-based panels in the panel furniture manufacturing industry, construction and decoration industry, the traditional universal circular sawing machine can not meet the needs of its processing technology, no matter the processing precision or production efficiency. Therefore, a variety of circular sawing machines dedicated to sheet metal cutting, a woodworking panel saw, has been rapidly developed. From small-scale panel saws with low-productivity manual feed or mechanical feed, to large-scale combination of digital program controllers or computer-optimized with automatic loading and unloading mechanisms with high productivity and automation The sawing system has been widely used in furniture manufacturing, building decoration, vehicle and ship manufacturing industries. Precision sliding panel saws are used for longitudinal, cross-section or angled sawing of plywood, particleboard, fiberboard, veneer, laminated board, blockboard, spliced solid wood and plastic panels to obtain dimensions The board meets the specifications and can also be used for sawing of various insulating sheets, thin aluminum sheets and aluminum profiles.

|

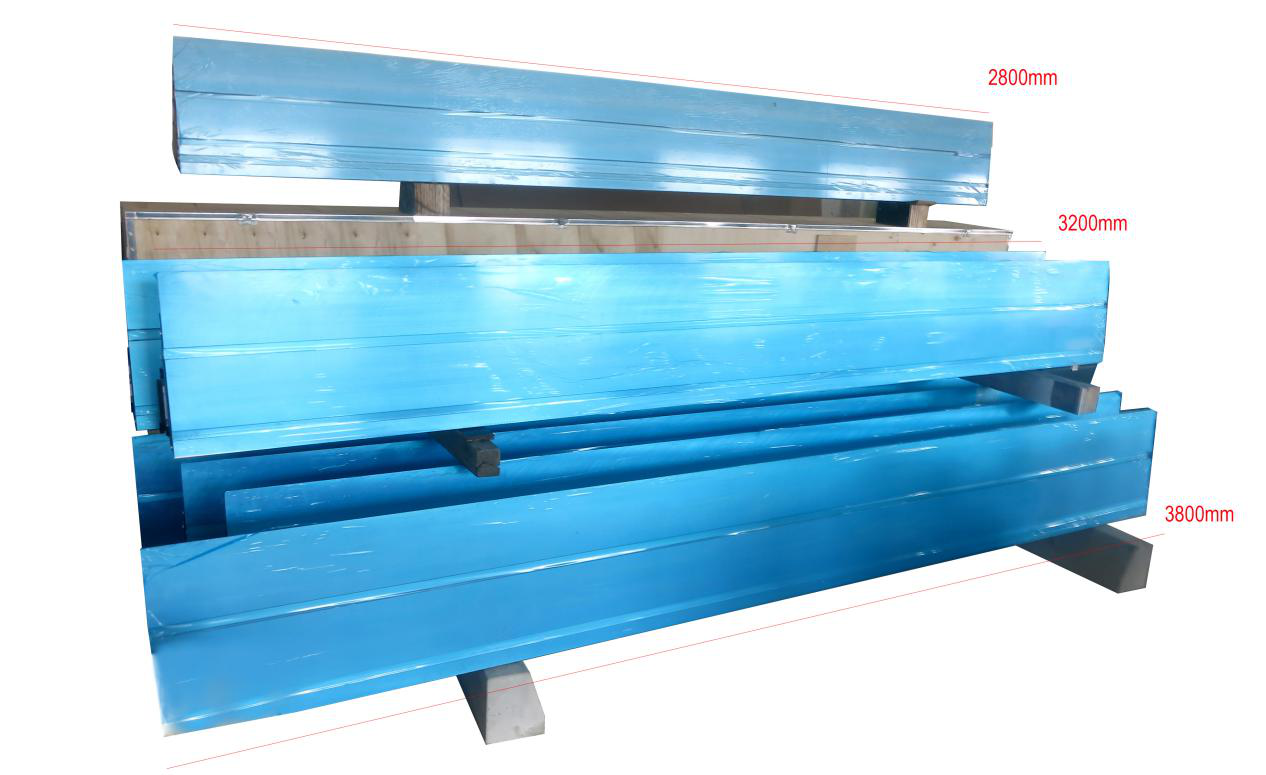

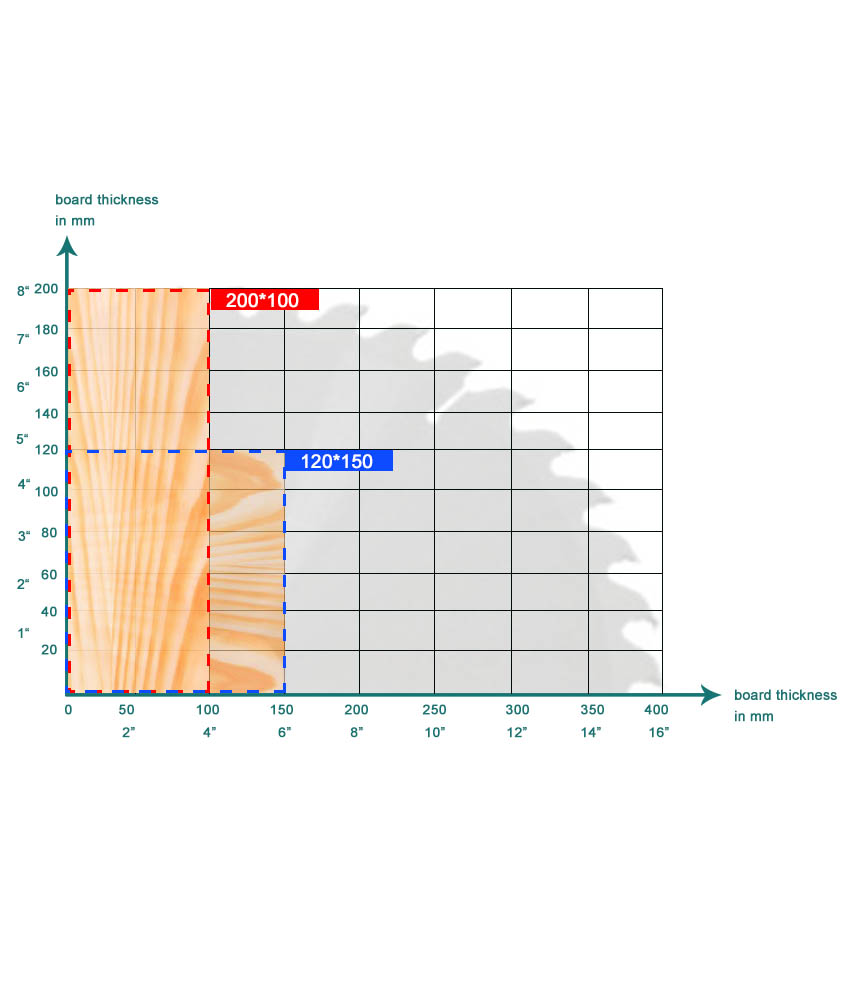

sliding table saw regular size

Precision sliding table saw pusher length regular size is 2.8 meters, 3 meters, 3.2 meters, 3.8 meters

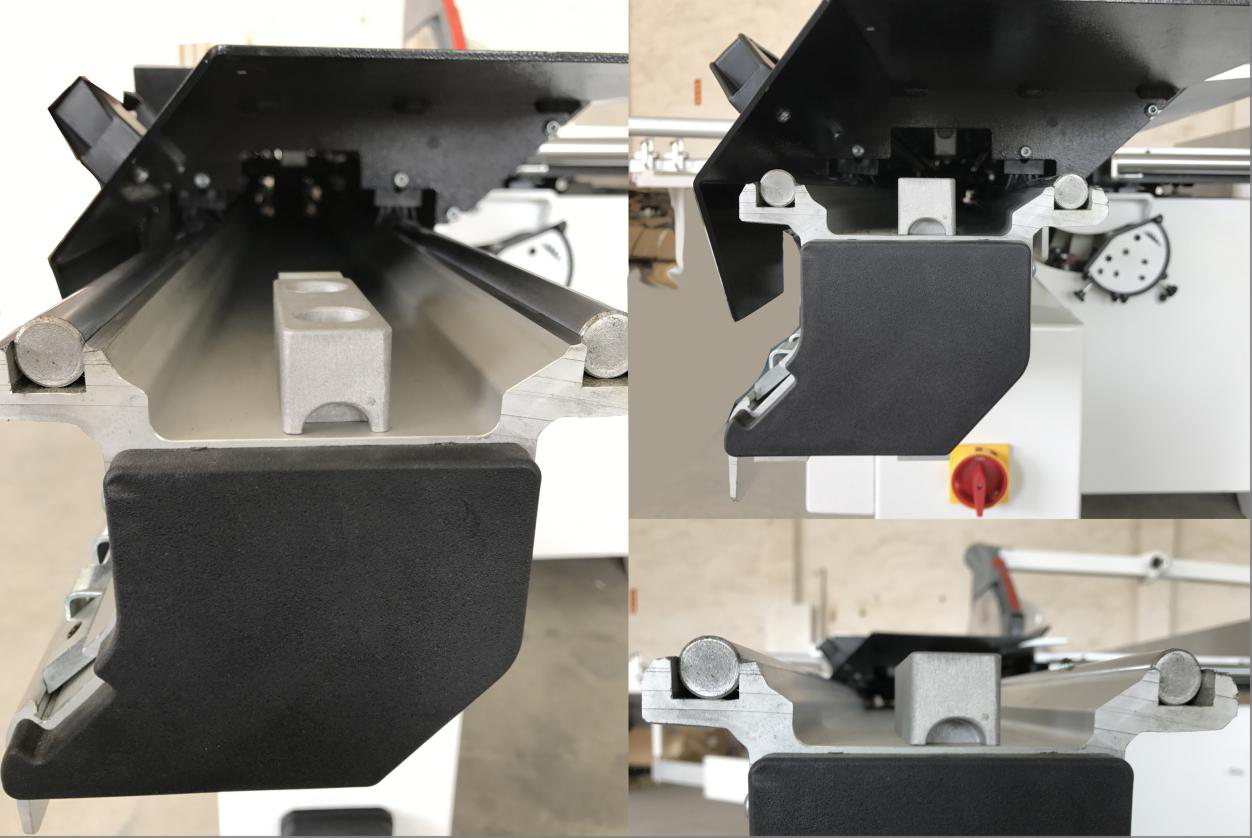

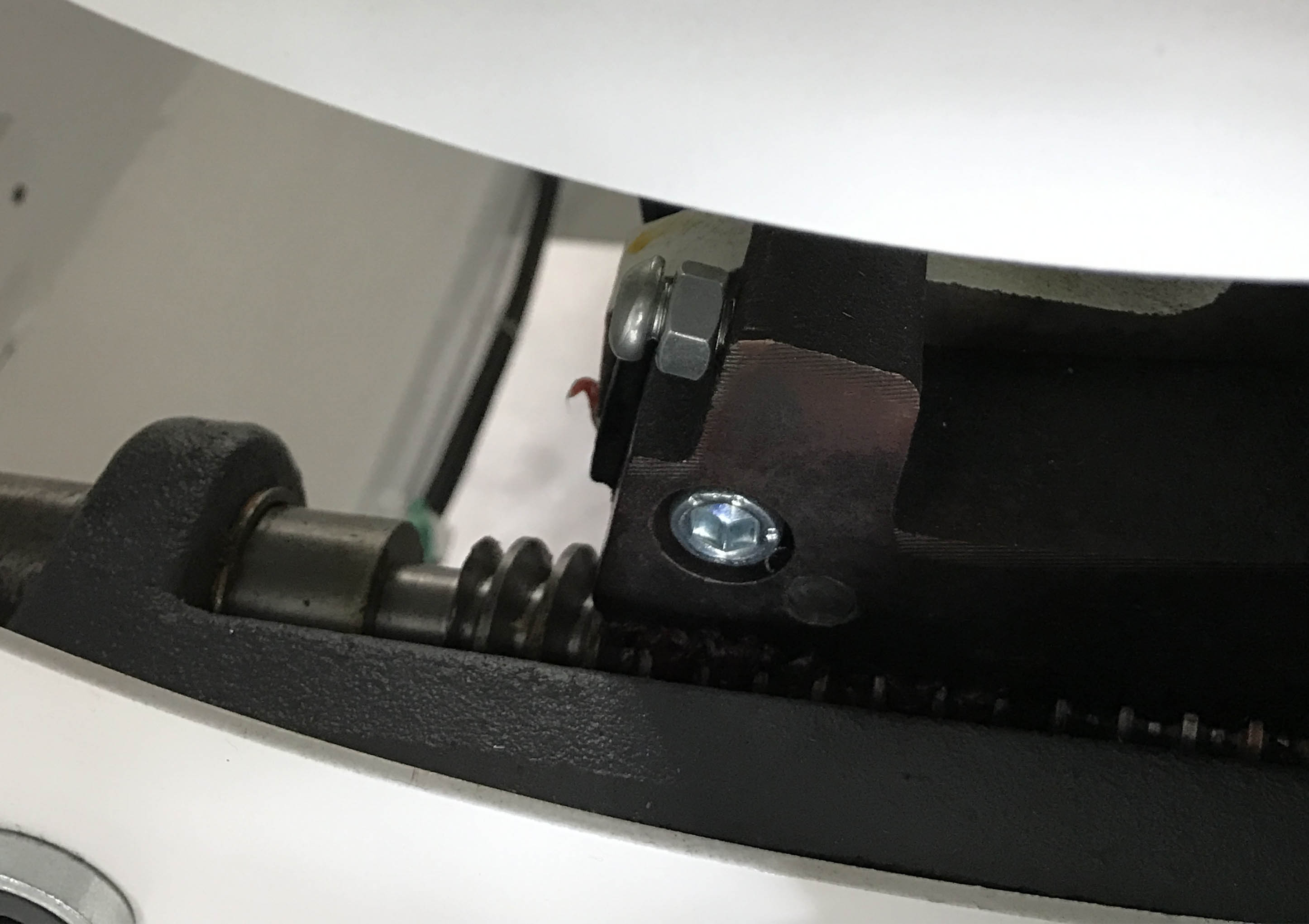

Precision sliding saws are usually divided into cylindrical guides and linear guides.

|

The advantage of the cylindrical guide is that the table slides more smoothly and is not easily deformed and damaged.

|  |

1, the structure of the host:

Casting movement

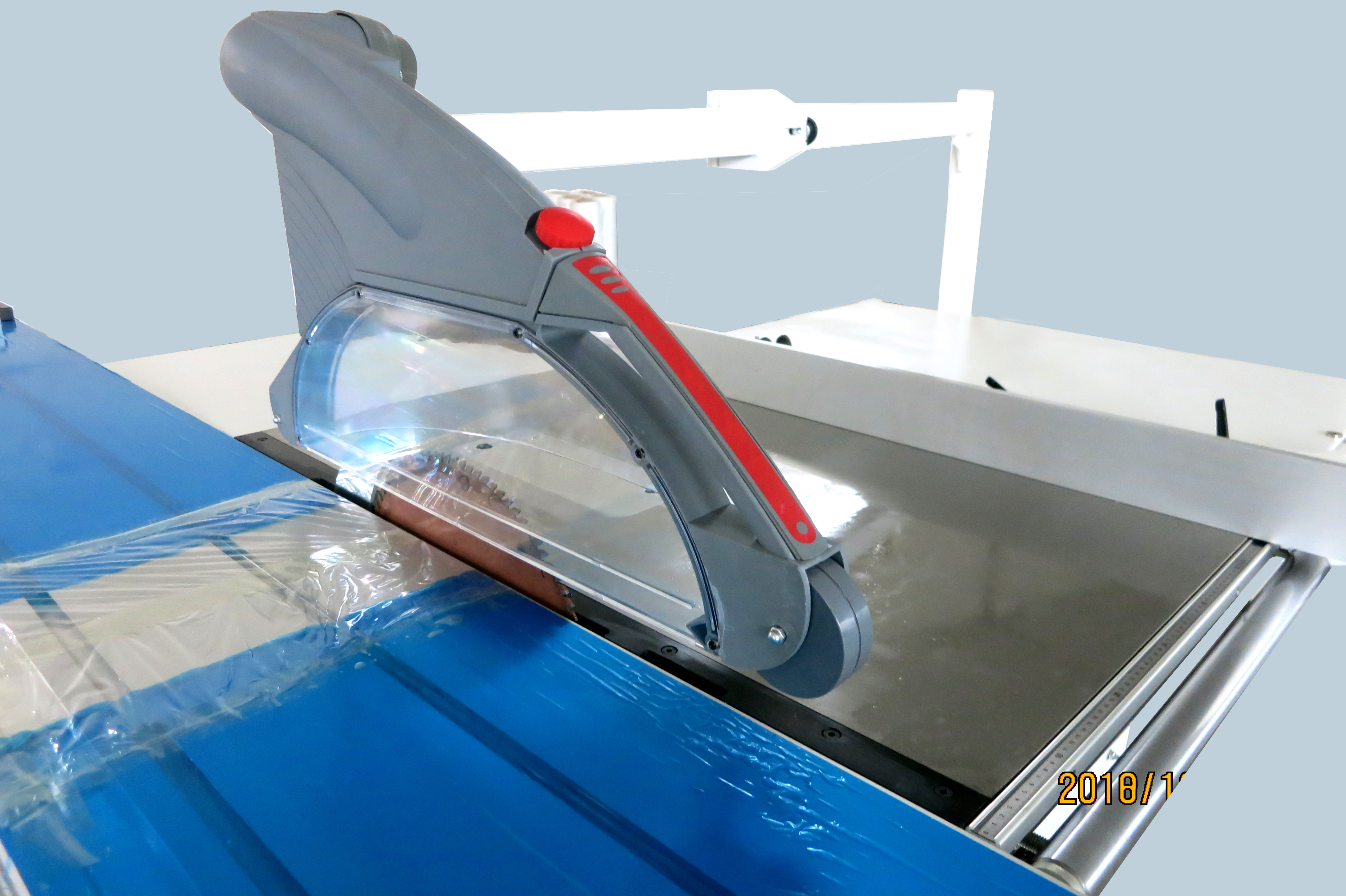

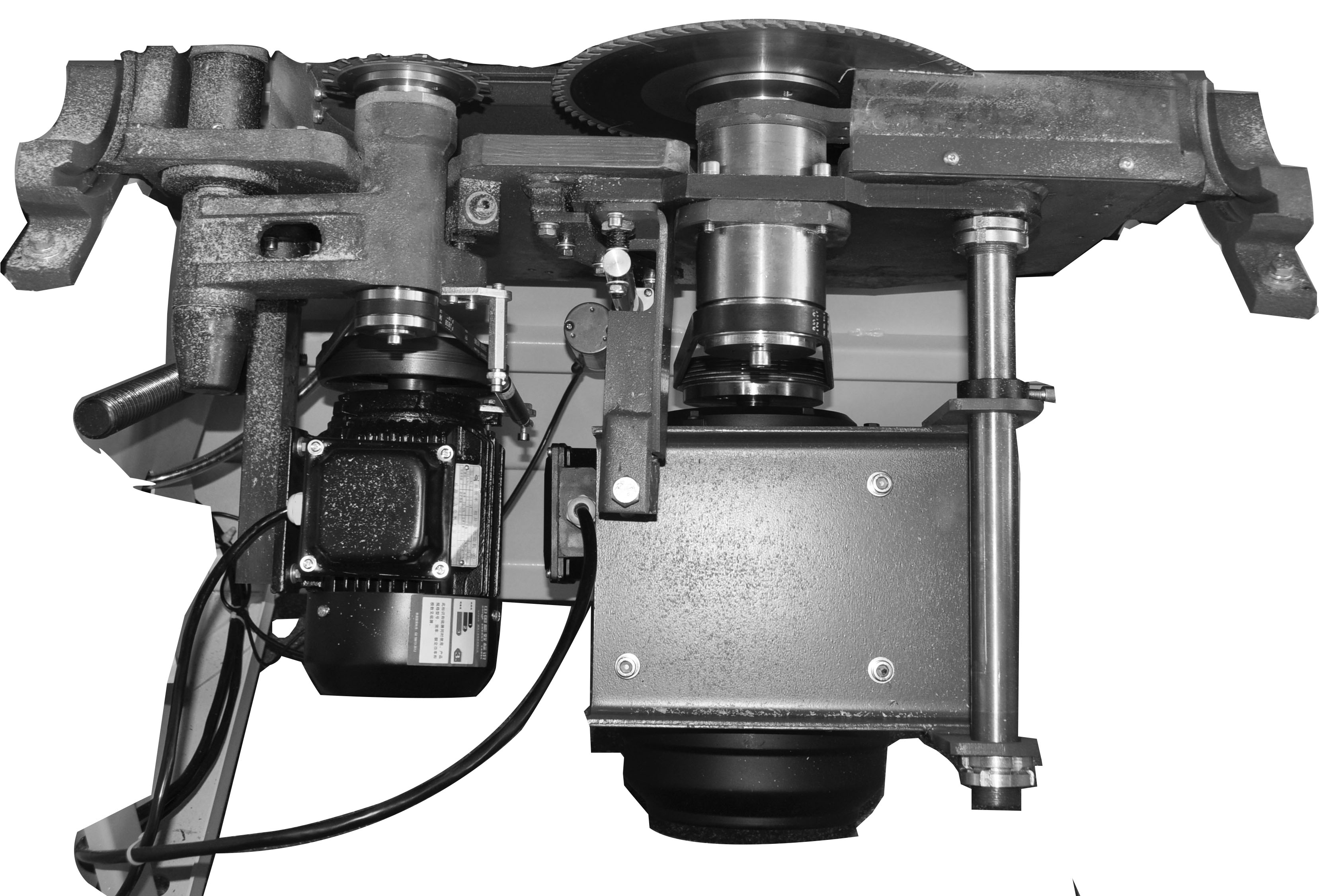

The main part of the precision sliding panel saw includes the bed, the table, the longitudinal section guide, the main saw, the scribe saw, the drive and other components. The structure and working principle are similar to those of ordinary circular sawing machines, and can be used separately as ordinary circular saws.

2. The composition of the sliding panel saw:

|

|  |  |

1) frame; 2) main saw part; 3) slot saw part; 4) transverse guide baffle; 5) fixed table; 6) sliding push table; 7) oblique saw guide; 8) bracket; 9) Saw angle display device; 10) side guide baffle

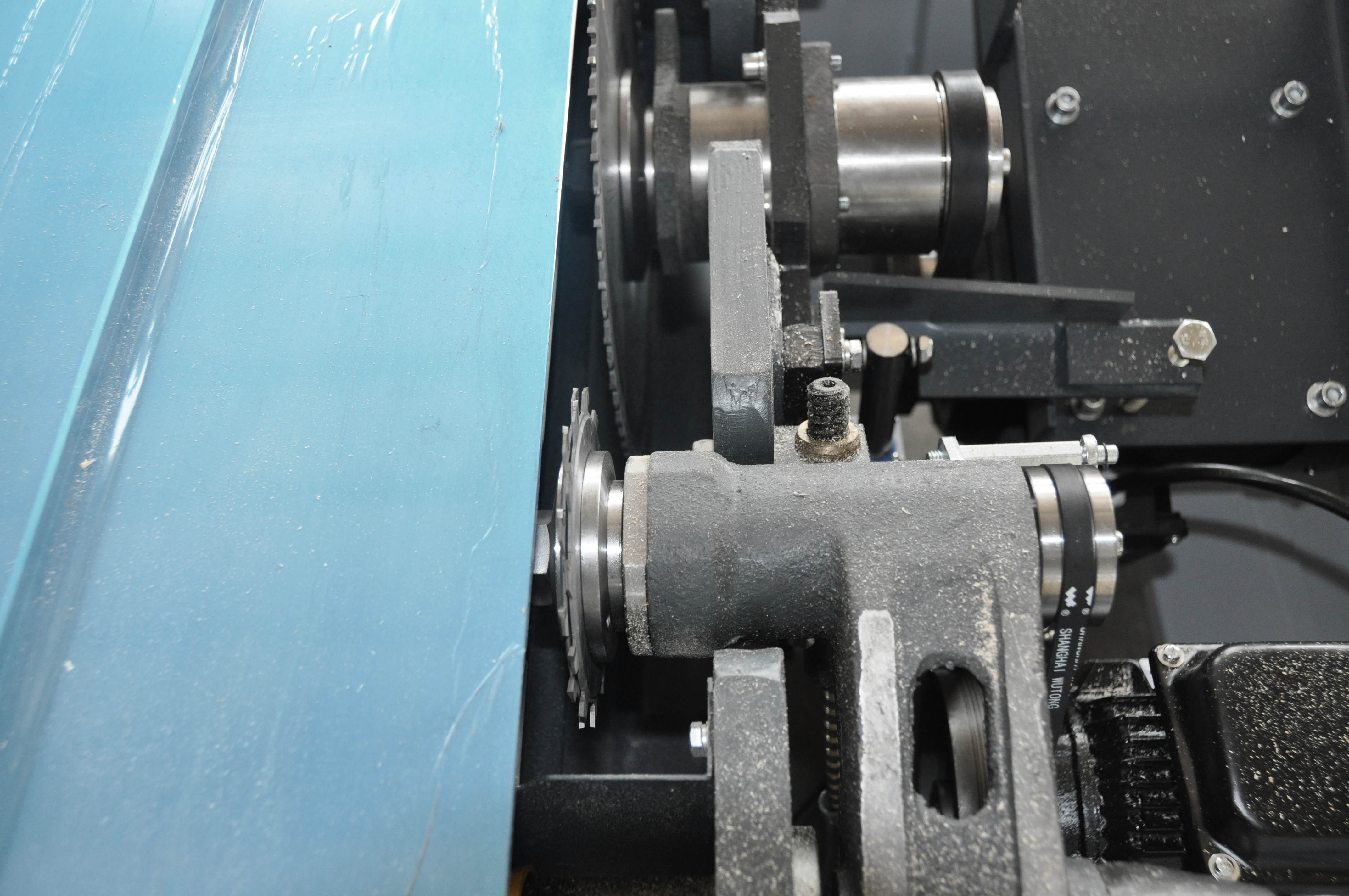

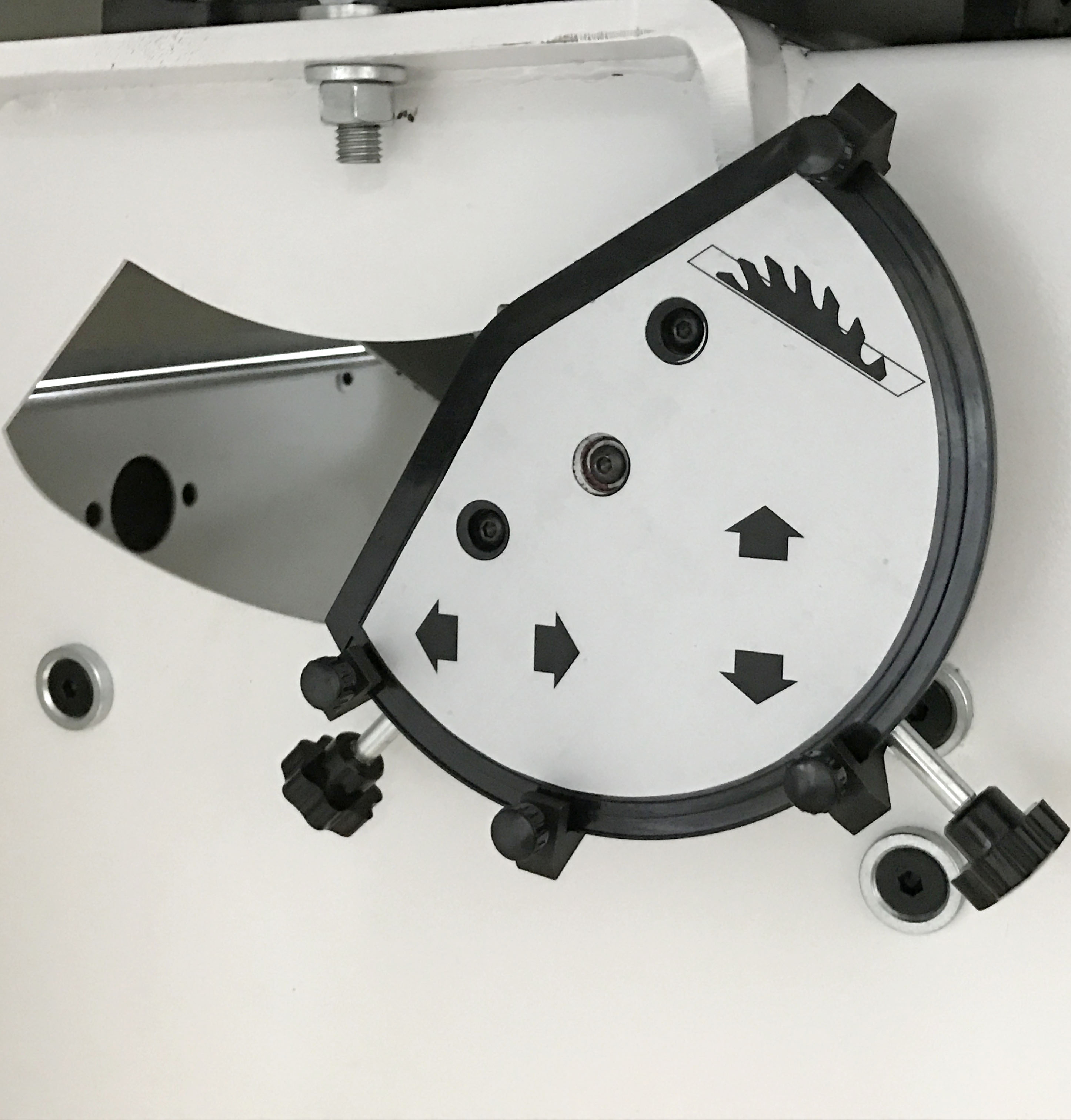

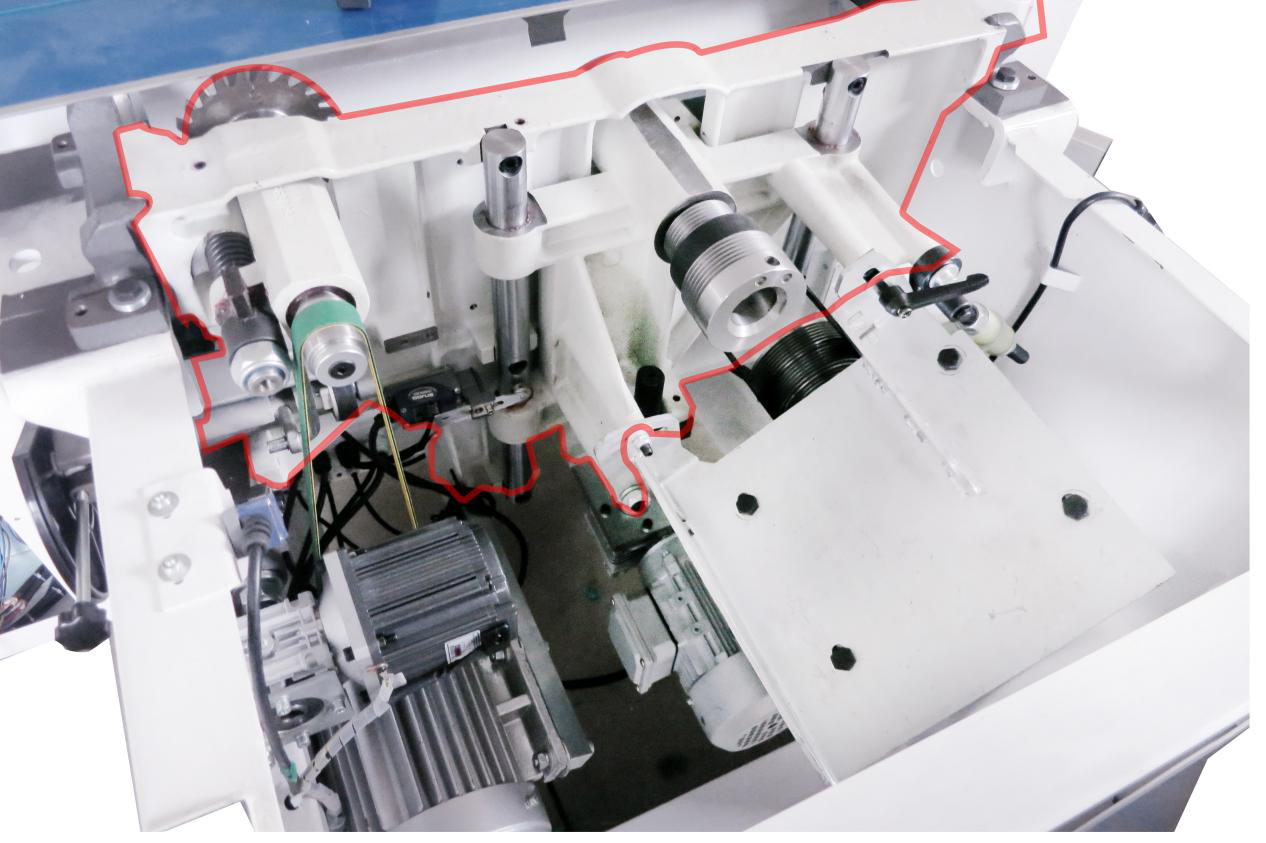

The main structural feature of precision sliding panel saws is the use of two saw blades, the main saw blade and the scribe saw blade. When cutting, the sawing saw is cut in advance, and a groove with a depth of 1 to 2 mm and a width of 0.1 to 0.2 mm thicker than the main saw blade is first sawed on the bottom surface of the plate to be processed. The edge of the kerf does not tear when the main saw blade is cut, resulting in good sawing quality. The scribe blade has a small diameter, usually around 120 mm, and is driven by a separate motor. The saw blade speed is generally above 9000r/min, and the cutting speed is generally 56-60m/s. The scribe saw blade is required to align with the main saw blade in the same vertical plane. The diameter of the main saw blade is φ8943; generally 300-400mm, which is driven by the main motor through the V-belt. According to the main saw blade diameter and the type of processing plate, the main saw blade can be changed by the tower wheel. The tower wheel shifting structure is simple and belongs to constant power output, which is more in line with the actual needs of wood processing. The power of the main motor is generally 4 to 9 kW. In order to make the speed adjustment easy to use special triangle belts, it is guaranteed that the single belt can meet the required power transmission. The rotation speed of the main saw blade is generally 3000-6000r/min, and the distance between the main saw blade and the scribe saw blade is generally about 100 mm.

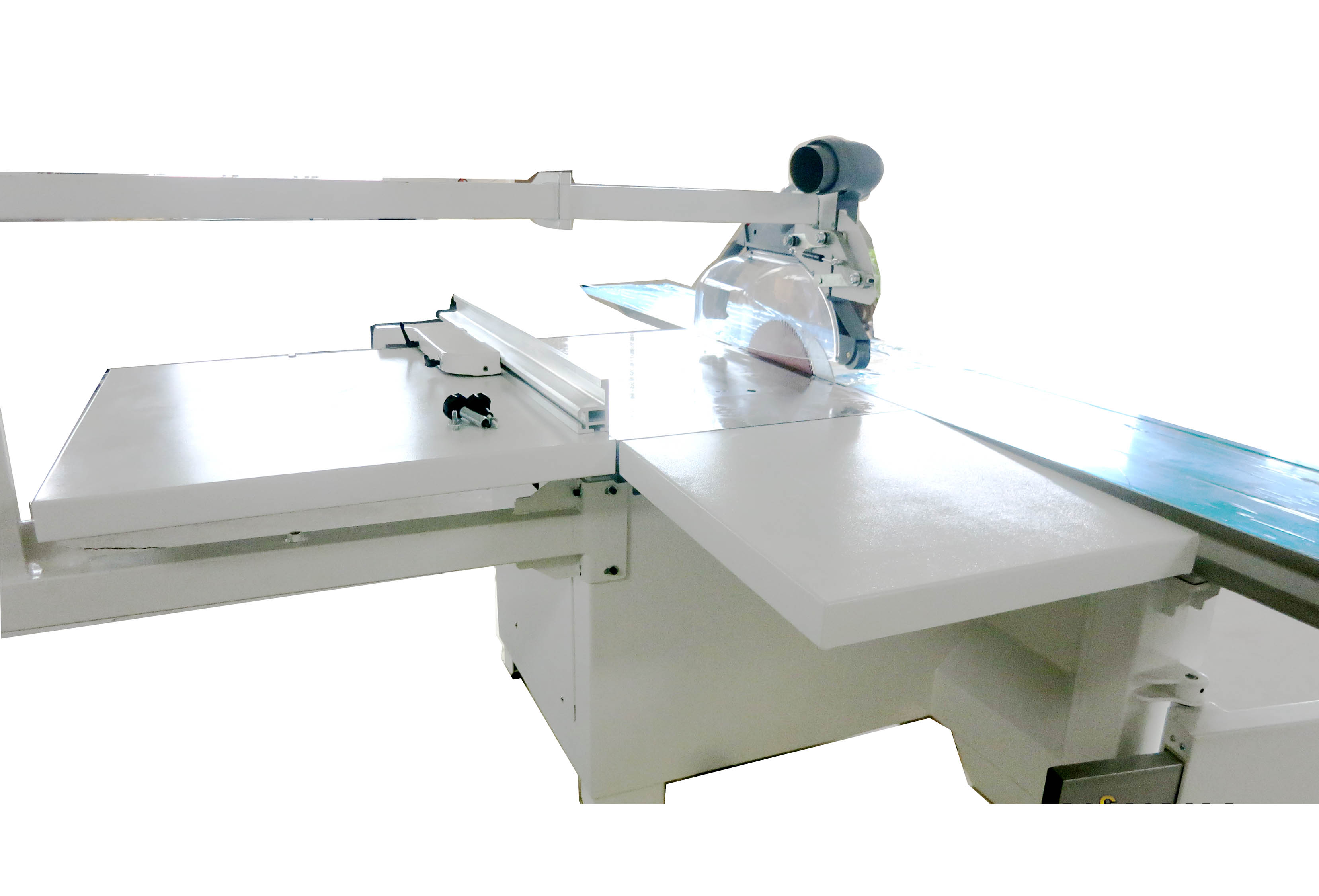

Another main structural feature of the precision sliding panel saw is that the scribing saw blade and the main saw blade are fixed, and the moving table made of the aluminum profile carrying the processed plate member is moved forward and backward to realize the sawing process. Due to the special structure of the guide plate of the moving table, the manual pushing and feeding is light and labor-saving, and the machining precision is high.

The bed of the precision sliding saw is mostly welded with a steel plate with a thickness of 5 to 6 mm. It is stable and beautiful, and can ensure that the early sawing process does not produce tilting and distortion. The fixed table is fixed on the top of the bed. The casting parts are required to be flat and not deformed, and are provided with a longitudinal cutting guide and an adjusting mechanism thereof.

|

|  |

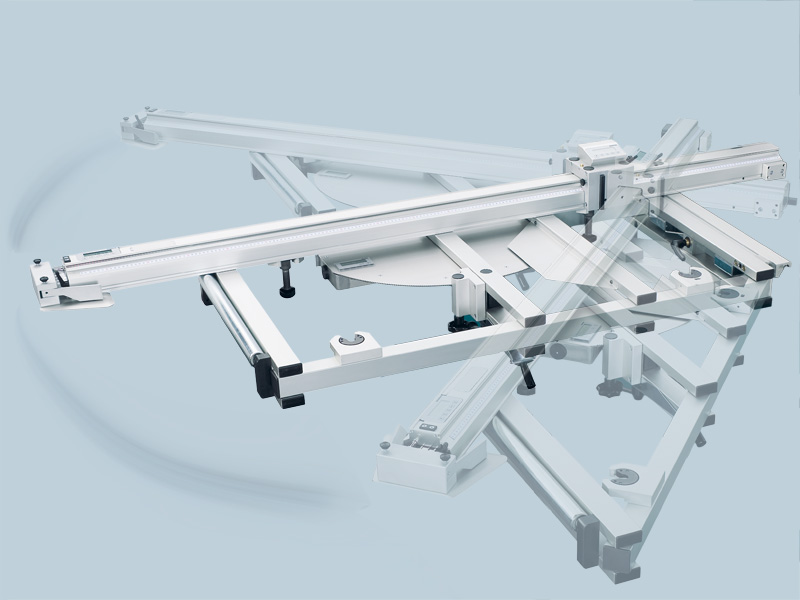

3. Structural features of the mobile workbench:

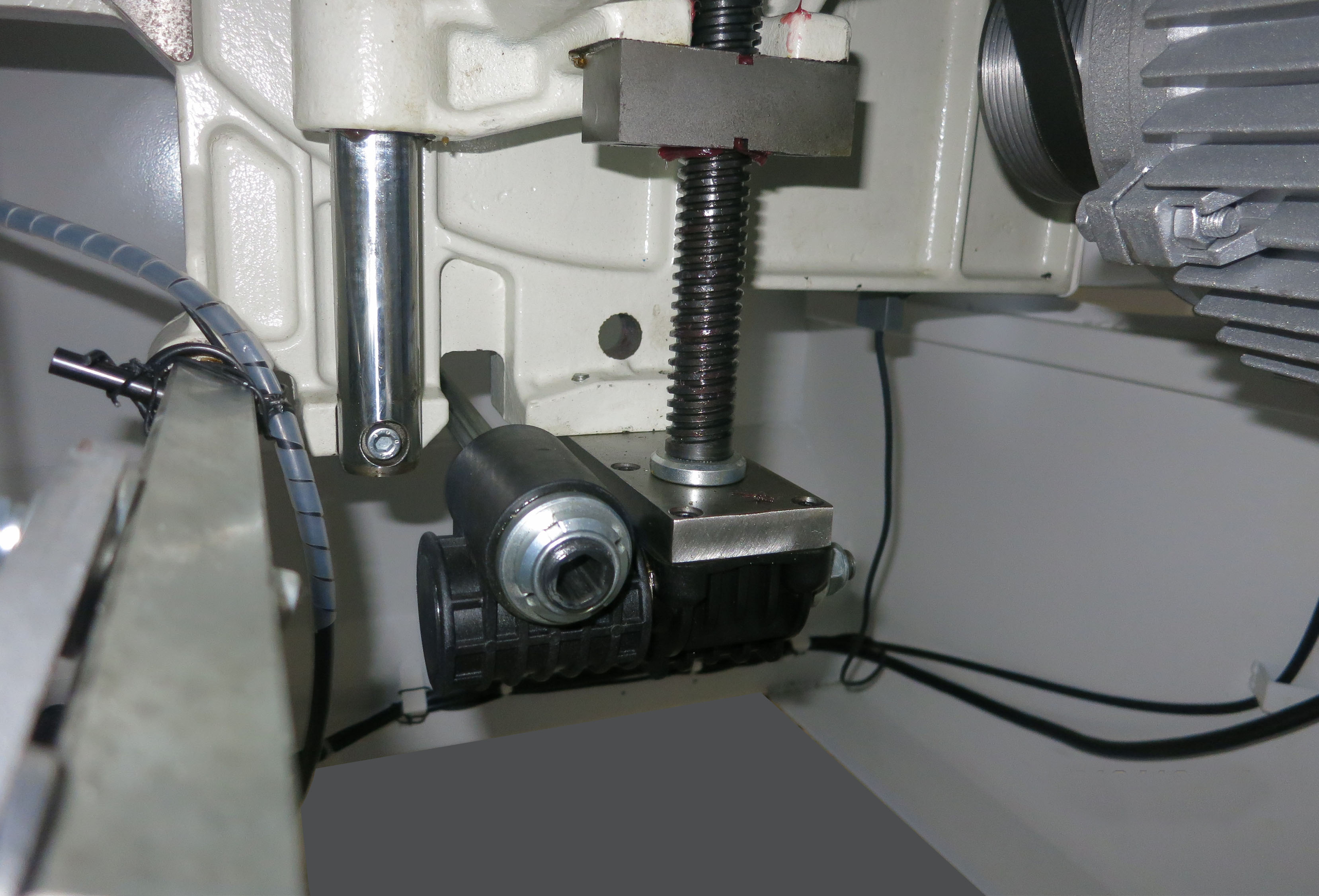

Pushing the mobile workbench is a key part of a precision sliding panel saw. It is also the main part of the ordinary circular saw machine. The mobile workbench consists of the bracket, the lower rail, the roller, the push table and other parts. Its remarkable features are: (1) light and labor-saving operation, large stroke, and large-scale research ;

(2) With a stable and lightweight trailer, the operation is stable; (3) The setting of the moving table and the main saw blade can be adjusted by 45 degrees, which expands the use range of the sawing machine. Some sawing machines are also equipped with milling devices. Grooves and tongue and groove processing with widths between 30 and 50 mm can be performed.

4. The use of precision sliding panel saws:

sliding panel saws are dynamically balanced or statically balanced. Under normal circumstances, the foundation is not needed and can be added on a flat ground. During the machining operation, the workpiece is placed on the moving table, and the moving table is manually pushed to enable the workpiece to achieve the feed motion. It is very convenient to operate, flexible and flexible. It should always pay attention to safety and prevent accidents.

7. sliding table saw operation notes:

1) Clean the table and the table top around the table saw.

2) Check if the saw blade is sharp and whether the size saw blade is on a line

3) Test machine: The time is about 1 minute. Check whether the machine is running normally. Check the rotation direction of the saw blade to ensure that the saw blade rotates in the correct direction.

4) Place the prepared plate on the pusher and adjust the gear size.

5) Start cutting.

8. Special considerations:

1) The plate should be close to the block and cannot be moved;

2) Adjust the cutting speed according to the thickness and hardness of the plate, and push the machine at a constant speed, not too fast.

3) When the small material is opened, the wooden strip is pressed and pushed forward.

4) The operator should wear a mask, can not wear gloves, can not wear loose clothes, can not leave long hair.

5) Do not directly pick the object by hand with the rotating saw blade. If necessary, use other long accessories to push it away.

6) If the corners of the plate are defective, consider replacing the blade.

7) After the cutting task is completed, turn off the power, and make the saw table and the surrounding 5S

9. Maintenance of the sliding panel saw:

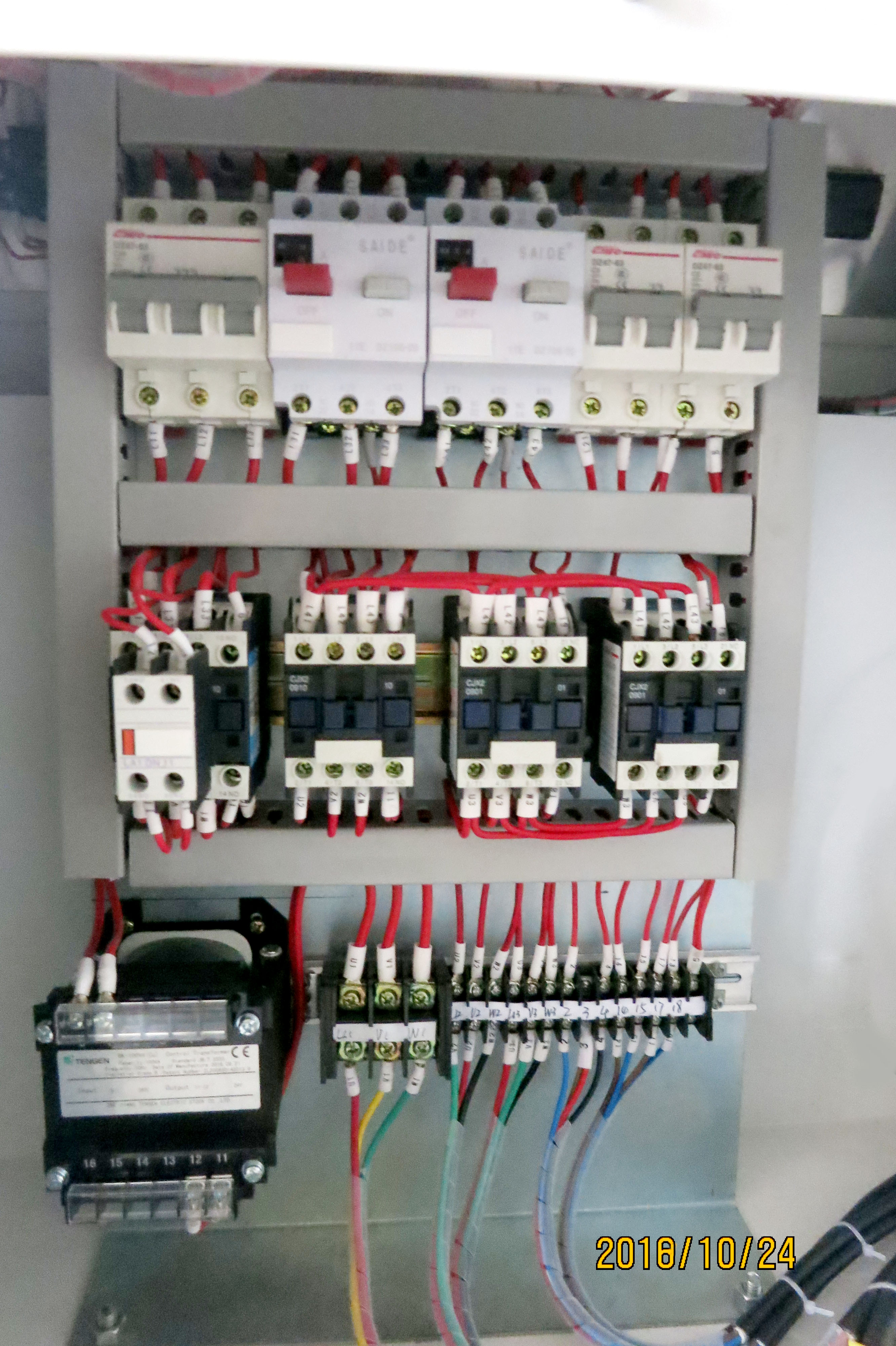

1) According to the workload, the dust removal operation should be carried out on the inside of the machine regularly to ensure the normal heat dissipation of the motor.

2) Regularly dedust the pusher track to ensure smooth running of the push table

3) Check the belt regularly and find that the wear should be replaced in time.

4) Regularly fill the lubricating parts of the fuselage to ensure the stability and quietness of the equipment operation.

10. sliding panel saw operation instructions

1) Before starting the machine, you must carefully check the saw blade pad and the compression nut and the screws at all parts. If it is loose, it should be tightened in time. When installing the saw blade, pay attention to the cutting direction and irreversible.

2) sliding saws do not allow the saw blade to work without a protective cover.

3) Precision sliding table saw When hand feeding, be sure to hold the wood close to the workbench and position the plate. The hand should not be too close to the saw blade. It is strictly forbidden to process wood that cannot be controlled by the hand.

5) Before processing, the wood should first check whether the wood is sawed at the place where there are nails, sandstone, joints, etc., in order to prevent damage to the saw blade and the joints flying out and hurting people.

6) The precision sliding panel saw can't stand in the cutting direction, and the operator should pay attention to safety when collecting wood.

7) When cleaning the machine, wiping the lubricant, removing the saw blade and removing the sawdust, the power must be turned off.

8) When the precision sliding panel saw fails, the power should be cut off immediately, and the operation should be stopped. The repair and adjustment should be carried out by a special person, and the machine tool is not allowed to operate with faults.