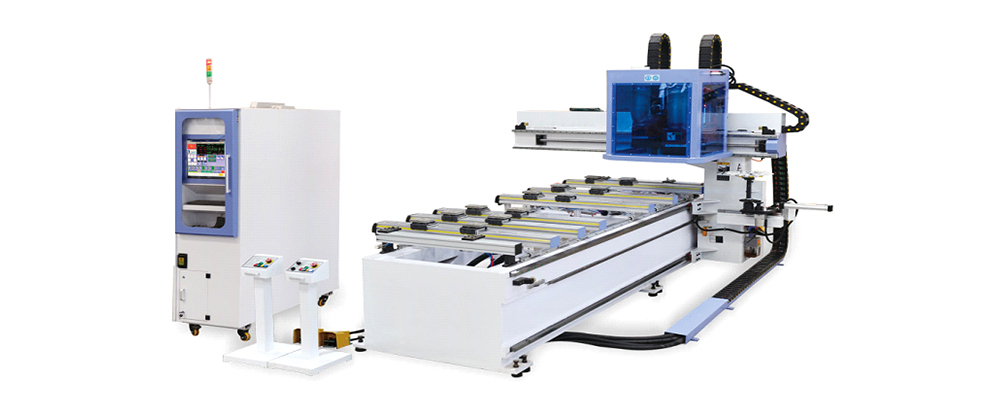

Cnc router detailed use introduction

1. Applicable industries: wood processing, cutting and carving on any kind ofMaking furniture, such as door, window, cabinet, craft wooden door, chairs and so on.

Advertisement: engraving and cutting various design on PVC, acrlic and soft metal.

Art craft: engraving characters or design of any languages and graphics for makingGifts and souvenirs.

2. Applicable material: wood, aluminum board, plastic, density board, wave board,Wave board, PVC, acrylic, crystal, light marble and other non- metal materials andLight metal materials.

3. Processing effect: any kind of engraving, cutting, milling, drilling, ect…..

some related instructions

1.the definition of height

2.according to the different material,engraving content,choose different tools, spindle speed, feed processing quantity.

3.file editor of sculpture of requirements:

[1] G code,carved document is the engraving machine instruction code.

[2] for the automatic identification documents,carved in the first row descriptor is starting in document"%",of the final end "!" as the beginning and end of work orders.

[3] data processing (machining accuracy)decimal reserved two, namely 0.01mm.

[4]G: this engraving machine code executed the G00 G01,code,two instructions moving fast moving and instructions.

[5]communication,using standardRS232 serial communication,baud rate amounts for 19.2K.8 bits of data bits,and master the computer for DSR/DTR handshake.

[6]engraving machine origin and editing software origin of contrast.

the zero point,editing software is the origin of carving machine. production process documents,0 point position directly influence the machining of starting position,should be determined according to the shape of the work piece position as the sword shall facilitate processing document "0" point to finish editing work.

engraving cutter

1.the equipment can be used for the 3.175mm diameter to carious cutting,6mm drilling tools, sculpture.random3.175mm,6mm provides two spring chuck.

2.the knife with random provides for the 3.175mm in diameter ,6mm tool,and 10,mainly suitable for hardwood and plastic engraving and cutting.carving,marble,copper metal cutting tool materials to another place.

3.by spring loaded knife: universal shuck with random small wrench stuck spindle neck flat,cannot,turn groove,reoccupy big wrench anti clockwise tight luosimu spindle ,the tool

Materials and clamping workpiece

This equipment is processed materials:organic glass,double-color board,marble,hard rubber,brass,copper,aluminum,stainless steel etc.hard processing double-color board,organic glass and soft weak plank used double-sided tape in random enclosed organic glass mesa.organic glass mesa in aluminum alloy with screws on table.organic glass surface of mesa of larger diameter can own milling cutter.the processing of metal,marble,because such hard material cutting force,in order to prevent the larger workpiece mobile,workpiece application t-shaped screws and embossed directly fixed in aluminum alloy,processing and stamp worktable and narrow piece of high,install a fixture in the clamping workpiece,will the fixture in processing.

Instructions:

Prepare

1. from the engraving machine electric wire cable to connect and the corresponding joint carving machines,inverter air plug connection to the four lines on the control box corresponding interface.

2. Check connections with controller(connecting line plug,aviation,the needle plugs line)in 9 RS232(joint) needle attachment from control box and computer serials communication interface(COM)

3. Check the connection spindle motor and pump,water supply conduit connect water pumps,inspection work is normal.

4. In order to avoid the socket loose or contact with bad product machining abnormal scrap,please choose good outlet,should have reliable grounding protection.

5. Switch on the power,the machine operation.

Start

1. turn on the power switch,the power indicator,machine first self-inspection operation,reset the X,Y,Z axis to zero,then,run to their initial standby position(machine)initial origin.

2. Using handheld controller respectively,the X,Y,Z axis alignment adjustment,the starting point of the carved work(processing)origin.on the axis of rotation speed,feed respectively,make proper selection of carving machines at work wait state.

Carving

1. edit the document to carving

2. Open file,the file to carving machines,automatic completion of work.Document.

End

After the end of the file,and when the carving knife,to be carved up and running to the staring point above work,press”pause/run”key twice,carving knife first opportunity to be on the cutting point position,in work wait states.this method can be used in the same lacation continuous replication products carved.

Engraving machine executes instructions for G/Hpgl code

Recommend using software

1. HICAS arving software.G code.

2. HICAS carving software.G code.

3. Type 3 sculpture software.Hpgl code.