Hicas Main Technical Parameter

| Edge Band Thickness | 0.4-3.0mm |

| Edge Band Height | 10-65mm |

| Edge Band Height (Pre-Milling Runs) | 12-36mm |

| Panel Thickness | 8-60mm |

| Panel Thickness(Pre-Milling Runs) | 8-32mm |

| Feeding Speed | 18-32m/min |

| Min.Panel Width | ≥60mm |

| Min. Panel Length | 50mm |

| Min.Panel Length(Pre-Milling Runs) | 100mm |

| Motor Power | 24.13kw |

| Working Pressure | 0.7Mpa |

| Overall Size | 9827*1000*1600mm |

| Net Weight | 5000kg |

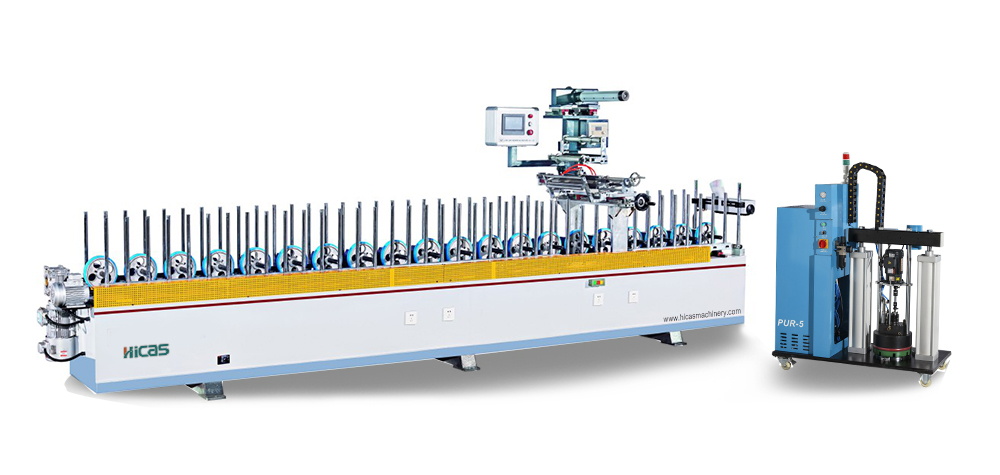

Full Automatic Edge Banding Machine

Application Market

With the improvement of quality of life,people have more and more requirements for practical furniture.eg,the price should be suitable, the appearance has to have style,ect.Naturally, there is a higher technical requirement for edge of furniture, and the demand of the edge sealing machine is long lasting. Whether it is custom furniture, or a large number of the same specifications office desk production. Edge banding machine has become an indispensable tool for individual carpentry, large furniture factory.

Function Introduction

This machine is suitable for medium density fiber board, blockboard, wood, particleboard, plywood and other linear polymer doors, edge trimming, disposable with double-sided adhesive tape cutting edge edge tape pressing, end-cutting, corner-trimming, rough trimming, refinement, scraping and polishing, edge and delicate, smooth, feel good a smooth straight line. The equipment is stable, reliable and durable, and the price is moderate, especially suitable for large and medium-sized furniture, cabinet and other plate furniture manufacturers.

Detailed Function Introduction:

Pre-milling:

It refers to the use of double cutter cutting, sawing by corrugated traces after burr or the panel saw/ vertical phenomenon, again modified, in order to achieve a better sealing effect. It makes the sealing strip close to the plate more closely, and the integrity and the beauty are better.

Glue seal edge:

Through the special structure, make the edge plate and edge material double coating evenly, ensure the adhesive force is more firm.

End-cutting:

Through the precise linear guide movement, it adopts the automatic tracking by the mold and the rapid cutting structure of the high-frequency high-speed motor to ensure the smooth and smooth cut surface.

Fine trimming:

It uses automatic tracking and high-speed high-speed motor against the workpiece structure to ensure that the upper and lower trim plate trimming smooth. Used to repair the edge of the processing sheet edge margin of the margin material. Fine knife R-knife. Mainly used for panel furniture, PVC, acrylic edge banding, 0.8mm thick edge banding is better.

Scraping:

It is mainly used to eliminate the ripple marks caused by the cutting process of the non linear motion of the trimming, so that the upper and lower parts of the plate are more smooth and tidy.

Polishing:

It refers to the use of cotton polishing wheel to clean the processed plate, the edge of the seal by polishing more smooth

Slotting:

It refers to the direct use of the side panels for the wardrobe, floor and other direct slot to reduce the sawing process panel more convenient and quick; can also be used for the door aluminum edge slotting.

Detailed Description

Double-sided adhesive, edge banding and base simultaneously glue evenly variable speed linear, special-shaped, electronic time control and travel control to send belt, cut with accurate length.

Offer

Manual edge banding machines are the best choice for irregular edge sealing or repair work.