Cnc Router The Daily Maintenance And Maintenance

Specific cnc router maintenance method

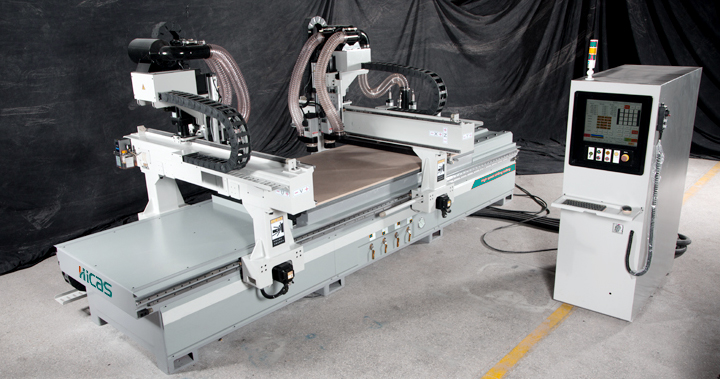

For a furniture factory, individual carpentry workers, have a very good cnc router is a very successful foundation. The daily maintenance of the equipment should not be underestimated. Here I will sort out the care and maintenance precautions of the CNC router machine:

I. Preventive measures for maintaining equipment

1. Before the work is completed or work, use a pneumatic gun to remove dust from the guide rails and the rack to prevent dust and lubricant from mixing and forming sludge into the slider, which may cause the slider to run unsmoothly.

2. Z-axis spindle guide (four steps as an example) Due to multiple sliders and short guide rails, automatic oil supply is not possible. Therefore, many manufacturers cnc router, usually once a week routine manual lubrication to ensure smooth and smooth spindle movement. It is recommended that the machine guide rail lubricant use guide rail lubricants. In order to avoid the busy work and forget about this maintenance work, our factory engineers, through the oil pump, and the intelligent control system, carry out automatic lubrication, eliminating the need for artificial lubrication.

Second, vacuum pump maintenance:

1. The maintenance of the water-cooled pump varies depending on the local temperature. When temperatures are high in summer, moisture evaporates rapidly. Check the amount of water in the tank daily to ensure that the water level is not below the minimum level, so as not to reduce the adsorption force. The lack of water causes the motor to burn out. The winter in the northern part of the country will be very cold. When the temperature is low, it is recommended to add 30% of antifreeze or 30% of ethylene glycol to the tank. Antifreeze or glycol is based on water. It is also necessary to check the water level regularly and add fresh water and an appropriate proportion of antifreeze/glycol in time. In case of cold weather, even if anti-freeze measures are taken, it is recommended that you turn the vacuum pump motor impeller before starting the vacuum pump to ensure that the vacuum pump does not freeze inside, so as not to burn the motor.

Dry rotary vane-type or maintenance-free/carbon-chip pumps usually only need to ensure lubrication, carbon film life is long, usually 1 - 2 years to replace the carbon film.