Different cnc router, producing different furniture.

How cnc router changed the production form of the furniture factory

Cnc router leads teenagers to enjoy the happy house of life

Together with the growth and development of modern cities, diy, home a lot more personalized, unique customization, high-end, young. The short pace of work, to ensure that young adults surviving in the city, rarely can pick the furnishings, sofa, bed, cabinet, wardrobe. However, the emergence of an machine has evolved it, which is - CNC ROUTER

Going home from work, a personal space, in line with my personal aesthetic furniture, a settee with additional features of its own, allow day of exhaustion, get released.

The cutting machine is an indispensable equipment for some light industry, and the woodworking machine is much more subdivided, plate furniture cutting machine, timber furniture cutting machine. And gradually develop, promote the market to improve cutting efficiency, reduce standby time (automatic loading and unloading system), expand the application surface, reduce operating costs.

Panel furniture cutting machine classification:

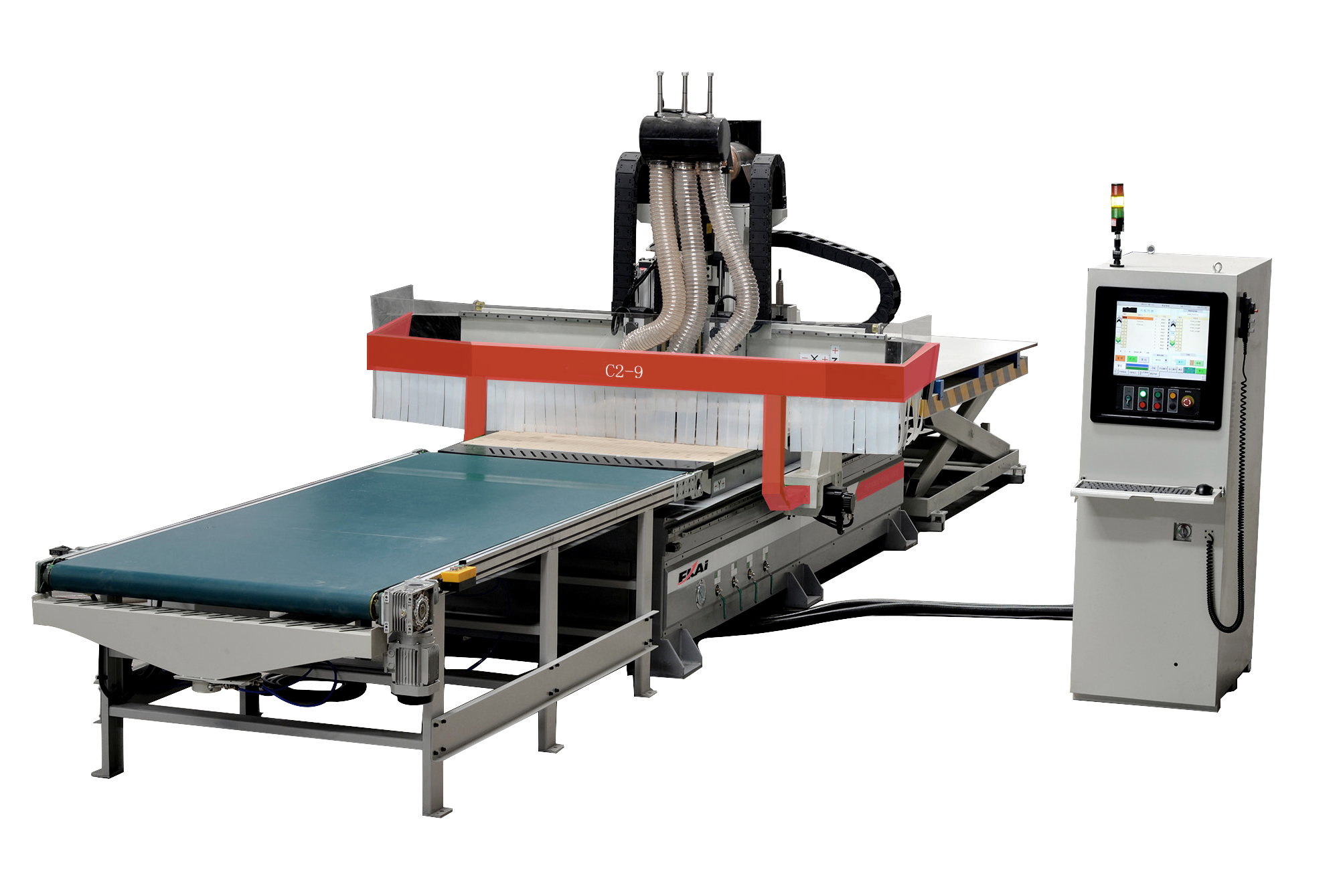

1. Three-step plate type furniture cnc router. One particular economical cutting machine, which is specially employed for punching, cutting and pulling grooves of panel furniture. A few heads work alternately. The factory has just started, the order volume is 200 boards per day, you can use this c2-9 machine.

2. Double station drill bag + double spindle cnc router center. A practical CNC punching and cutting machine, equipped with a two-spindle pneumatic tool changer, the way of row and drill come together, professionally useful for punching, cutting, pulling and also other processes of panel furniture. The double head can function alternately. This machine is punched with a slightly faster rate, and the boss with plenty of budget suggests it.c2-04

3. Automatic punching and cutting machine machining center. CNC standard type plate furniture processing center, this machine can realize back plate slotting, vertical punching, rectangular cutting, profile cutting, realize feeding, positioning, punching, slotting, cutting, blanking, automatic labeling, etc. . At the same time, it is furnished with special deduction optimization software to optimize layout and lower board waste. Professional panel furniture production line, for that growth of production scale, or concentrate on custom furniture furniture manufacturers, the cutting machine is the foremost choice.CA12

4. Double gantry panel furniture cnc router. High-efficiency new type of material-cutting machine that saves space and space. Of course, it can realize slotting in the back plate, vertical punching, rectangular cutting, profile cutting, material feeding, positioning, punching, slotting, cutting, cutting, automatic Labeling and other functions. Now were making a lot of furniture factories which are tied to the factory area. We would like to put more feeders within the smallest workshops, reduce production costs, minimizing the economical burden for purchasers who buy furniture.

Panel furniture cutting machine equipment analysis:

1. The panel furniture cutting machine greatly raises the utilization rate with the board. Using the milling cutter, the direction with the milling cutter might be adjusted arbitrarily based on the needs of the wood, so your transparent planks may be cut quickly, and also the average utilization rate of each and every board is 2.7-2.8 square.

2. The panel furniture cutting machine effectively saves labor. The panel furniture cutting machine can operate several machines by anyone, and it can be utilized with the edge-turning line. It's completely controlled by the machine, as well as the manpower can just manipulate some easy steps.

3. CNC woodworking machine greatly reduces labor intensity. The labor price of the enterprise has long been an important part of the enterprise capital chain. Effectively reducing the labor cost can greatly increase the cash chain with the enterprise.

4. CNC woodworking machine features a fast material opening speed. The CNC cutting machine uses the mechanical arm to be effective continuously, and will work continuously for 24 hours without the interruption. The precision is high.

5. Panel furniture cutting machine is small in dust. The most up-to-date vacuum technologies are accustomed to make sure that panel furniture cutter won't dust during work.

Needless to say, cnc router supplies a technical level, along with a machine with a more efficient completion rate. However it is thinking. All things considered, approaching the way in which robots effort is the true secret to finding the job done. Our software is also put together by ourselves and hang into used in a huge number of furniture factories. Therefore, in order to make your own furniture better serve more and more people, let more and more people like it, depend on your furniture, please understand our cnc router, in fact, we have been professional suppliers.