|

the most cost-effective furniture production model

The most cost-effective furniture production model

Furniture production machinery, how to ensure the cost and quality of furniture

The style of furniture is becoming more and more independent, and the form of furniture production has become more flexible and diverse. Therefore, the furniture production line needs to have the most efficient and flexible production form and variability, and can be customized, which has become the demand trend of the furniture factory.

|

|

The use of furniture, whether in the home or in the office, begins to become lighter, easier to assemble, and less expensive. And the market is changing rapidly, and the style and style of furniture is changing every year. For the furniture machinery manufacturing industry and the woodworking machinery industry, more competitive requirements have been proposed. The entire furniture production line, the price should be controllable, not too high. The production process is simple and requires fewer operators. Small footprint, stable production, and timely after-sales service.

|  |

The author, met several experts in the furniture industry, the author himself also engaged in 15 years of experience in the woodworking machinery industry, combined with several woodworking machinery industry exhibitions in 2018, combined with the trend of high-end furniture factory production. Share with you, the most cost-effective furniture production model.

Plate selection

|  |

1. MDF The most cost-effective, high-quality furniture sheet is generally used for medium and high-grade panel furniture. MDF is made of wood fiber or other plant fiber, which is made of resin and other adhesives. It is pressed at high temperature and high pressure and has a density of 0.50-0.88G/cm3. Features: fine wood, strong bending strength, easy to process, especially suitable for curved and profiled designs. Avoiding defects such as scorpions and insect eyes, it has small expansion and contraction, no warping and no cracking, smooth surface for easy sticking of thin wood, no processing defects, strong bonding force and strong nail holding ability.

2, triamine plate (ie melamine plate, environmental protection board) MDF or particle board on the surface of high temperature and high pressure paste melamine paper decorative board. Features: water resistant, heat-resistant and wear-resistant, high finish, stable performance, rich colors and beautiful appearance. The surface is a plastic film and no chemical gas volatilizes.

|

|

3, particle board (that is, particle board, bagasse board) using a variety of mechanical shavings or some wood chips through the hot mix of hot mix. Features: loose material, light weight, strong nail holding power, good moisture and water resistance, easier to control the amount of formaldehyde released, not easy to deform, etc., suitable for use in furniture flat areas. Its shortcomings are large particles, not suitable for painting, engraving, plastic molding and other processes and thin plates. There is no good or bad particleboard with medium density under quality assurance conditions.

4, plywood (commonly known as splint) The wood is softened and then cut into veneers, then dried and glued, the wood texture is interlaced and stacked, and pressed by a hot press. Features: good sound absorption performance, strong temperature adaptability, in different temperature areas, the shape of the plate changes little, not easy to deform. The surface is rough, the adhesion is strong, and the effect of sticking veneer is good. It is lighter than MDF, has strong pressure resistance, and has poor water swelling. But the nail holding power is weak.

5,The veneer has the following forms:

|

A, original veneer veneer: common veneer color from light to deep, there are cherry wood, maple, white peony, red sorghum, ash, white oak, red oak, teak, huanghuali, red pear, walnut, White shadow wood, red shadow wood, red sandalwood, ebony and so on. In the production, the solid wood is cut into wood chips about 2 mm thick, which are attached to the surface of the furniture by special adhesion, and then painted and UV-baked. The characteristics are smooth touch, and the wooden board with a finger buckle has a thick feeling and a surface grain. Clear but irregular, you can see a veneer of about 1 mm at the corner of the plate. This kind of furniture is the top grade in veneer furniture, and the price is generally slightly more expensive.

B. Log composite veneer: layered with layers of different colors of raw wood, glued to form wood by high-pressure glue, and then sliced ??from the section to form a new type of veneer with different colors and different wood species.

C, log color leather: This kind of furniture is relatively cheap, the general price is 2/3 to 1/2 of the wood veneer, but it is more likely to be scratched and rolled up in use.

D. Plastic veneer: This kind of veneer is a petrochemical product. The surface is printed with wood grain and floral decoration by special printing machine, and the back is made of rubber. It is made by hot pressing precision instrument.

E. Fireproof board: The fireproof board is wear-resistant and not afraid of hot. It has wood grain, plain surface, stone pattern or other floral decoration, and is mostly used for panel furniture and kitchen utensils.

The most cost-effective furniture production model composition of the furniture production line (machine selection)

|

cnc router - cnc boring machine- automatic edge banding machine

Furniture design software

a highly modular integrated software designed for cabinet wardrobe manufacturers to accommodate any size business from design to production, from store to factory, from front to back. The software mainly includes four modules: precise design, automatic splitting, optimization of typesetting, automatic machine access and processing code.

cnc router features introduction:

1)It is economical and efficiency equipment, suitable for small and diversified production.

2)Work table can adsorb the entire board directly, no need any cutting preparation action.

3)It’s high precision and efficiency equipment, suitable for the production mode of the milling and drilling compound machining.

Can equipped with any combination of vertical drilling, single drill, row drilling and other multi-functional drilling mode

4)Multi-process cnc router, all calculated as computer calculation, zero error, zero failure rate. The operation is simple, the high-end cutting machine is 80 sheets per day for 8 hours, the ordinary cutting machine is for manual loading and unloading, and the artificial rest can be taken during machining, which greatly reduces the labor intensity.

5)Improve the utilization rate of the plate, the cutting machine uses the milling cutter to open the material, can arbitrarily turn the direction of the turn, can cut the opposite sex, the push table saw must be opened. The dust of the cutting machine is small, and the dust suction effect of the multi-process cutting machine is much better than that of the table saw.

6)Reduce labor intensity, save labor, push table saw 2 personal operation one, multi-process cutting machine one person to operate a few, saving the manpower of the push table saw, the plate is used more. The multi-process cutting machine has a fast feeding speed, the cutting machine is continuous when working, the push table saw pushes and stops, the board is moved to the place, the workers' strength and time are spent on the board.

|

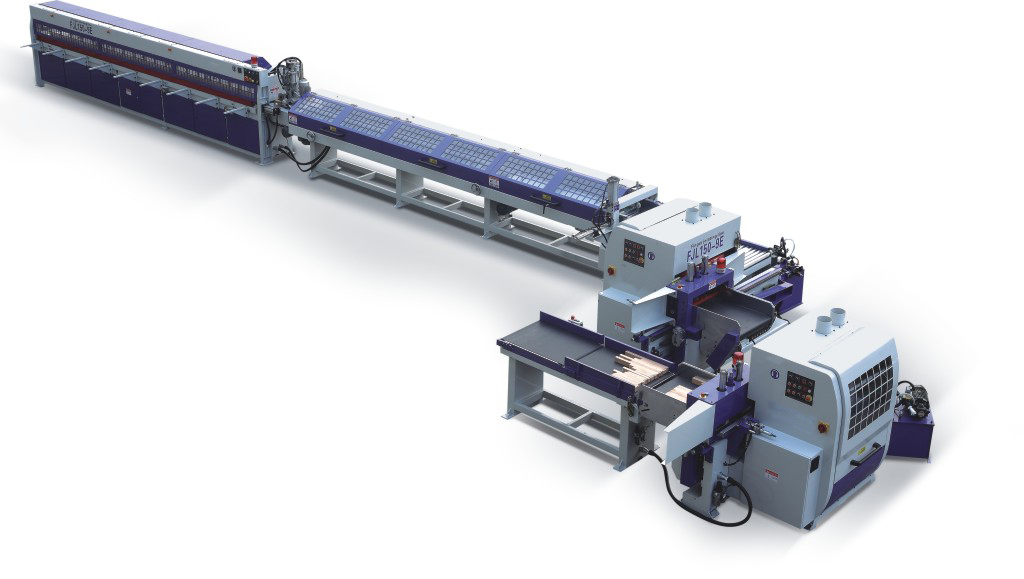

cnc boring machine features introduction:

1. It can quickly and accurately disassemble the order, design and realize automatic and accurate splitting at the same time, without manual intervention.

2. The plate utilization rate is extremely high, even the irregularly shaped plates can be accurately budgeted and arranged in the optimized typesetting module built into the software.

3. Seamless docking CNC equipment

4. The design process automatically generates the quotation and price list in synchronization, and can select the quotation standard and the pricing method according to the needs.

Designed for the development of panel furniture, suitable for all kinds of cabinet wardrobes, panel furniture design.

|

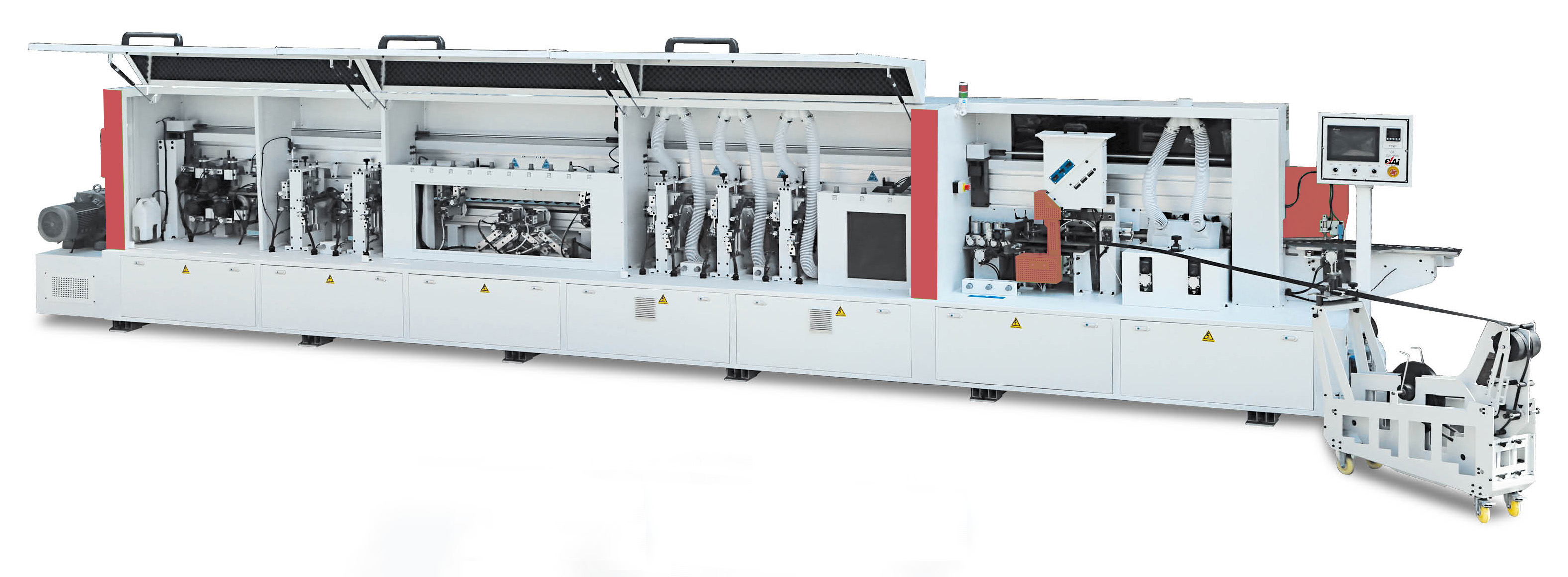

automatic edge banding machine features introduction:

1. Simple operation, automatic five-sided punching and slotting cutting process can be realized in one workpiece clamping.

2. With four working areas, four different sizes of plates can be processed at the same time, and the production efficiency is doubled.

3. The fuselage adopts heavy steel structure and the manufacturing precision is extremely high.

4. It can be positioned by laser scanning without scanning code.

5. Can support a variety of panel furniture design and production software.

6.After machining is finished, the material is automatically discharged, manually sorted, and the work efficiency is high. The labor production is low, the output doubles compared with the traditional connection. The automated production line is the main production method in the future: saving labor, high plate utilization rate and high processing efficiency. If you consider the investment In the previous period, you can do it separately from the cabinet and the cabinet door. That is to say, you can choose one of them first, and then do it all afterwards. Specific can be combined with their own sales methods.

Mainly used for edge sealing of panel furniture.

Features introduction:

1 The hook-type tank chain is used to completely solve the running version caused by the short edge of the edge.

2. The belt type pressing device is adopted, and the pressure plate is stable and reliable.

3. It can be equipped with plate preheating device. When the indoor temperature is too low, it can solve the problem that the edge band is not firmly adhered by heating the edge of the plate.