| Model | FJL150B |

| Infeed length | 150-900mm |

| Shaping thickness | 20-150mm |

| Max working width of shaping table | 590mm |

| Pressing thickness | 20-80mm |

| Pressing width | 30-150mm |

| Shaping spindle diameter | 50mm |

| Shaper spindle speed | 6750r/min |

| Hogger spindle diameter | 30mm |

| Hogger spindle speed | 2840r/min |

| Max pressing length | 2500mm |

| Max thrust force | 7500kg |

| Shaper spindle power | 11kw*2 |

| Hogger power | 4kw*2 |

| Scoring saw power | 0.75kw*3 |

| Hydraulic system power for press | 4kw |

| Saw blade power for press | 4kw |

| Total power for belt conveyor | 0.75kw*2 |

| Total power of roller conveyor | 0.75kw |

| Total power | 42.5kw |

| Working air pressure | 6-8 bar |

| Wind measure of dust collector | 9000m3/h |

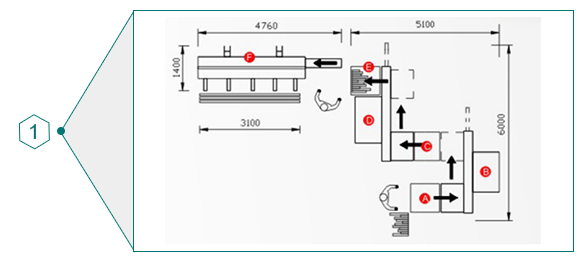

| Fixing dimensions | 8000*6000mm |

Advantage:

1. Guide rail of finger joint shaper’s conveyor is japan precision linear guide rail to gurantee the shaping accuracy .

2. The design for finger joint shaper is double blades+tooth-tenon knife assembly to provide high precision.

3. The conveyor table of finger joint shaper adopts German pneumatic hydraulic conveyor system to control bakc and forth ,smoothly,low maintenance,high quality .

4. The second push part of finger joint assembler adopts long+short double pushing board design,by this kind of structure ,it can assemble very short workpiece to reduce the cost .

5. Whole machine is conveniently operated by PLC Central integrated programmable controller.

Packaging :

1.Stretch film and plastic film for humidity.

2.Standard marine export plywood case.

3.Pallet packing.

Shipping:

1.We support maritime and land transport.

2.Shipped in 15-30 working days after payment.

If you have any requirement or question, please fill out the form below that we will reply you within 24 hours.