| Model | C2-9 cnc router |

Working Table Dimension | 1220x2440mm |

| X Y Z Working Area | 3150*1780*250mm |

Top And Bottom Stroke Of Spindle | 150mm |

Workpiece Height | 100mm |

Max Moving Speed | X axis :60m/min Y axis:60m/min Z axis:15m/min |

Spindle Type | Manual cutter spindle |

Main Shaft Speed | 3000 – 18000 RPM |

Vacuum Area | four vacuum areas |

High Frequency Spindle Horsepower | 2X6KW |

Vacuum Pumping Horsepower | 10HP(7.5KW)-250m 3 /h |

Cnc Controller | Taiwan new generation system |

Standard Configuration | Toolbox, equipment operation manual |

Drill Shaft System | 9V Italy FAM |

Vertical Drill Shaft Number | 9 |

Drill Shaft Horsepower | 1.5kw |

Rotation Speed Of Drill Shaft | 3200 rpm |

Pitch Of Drills | 32 mm (1.26") |

Drill Shaft Stroke | 70 mm (2.76") |

Software | E- wood software |

![]()

The machine body welded by 150 * 300,150 * 200 rectangular tube and 10 mm steel boards, high rigidity and high strength. 24 hours tempering process after welding, then sand blasting, spray primer, processing, shaving putty, spray paint.

![]()

The beam must be escrape, let the guide rail rack and machining surface fitting, each assembly by playing table method to measure accuracy.

![]()

Assembly, it’s produced by assembly engineer with over ten years experience in this industry. We use Taiwan TBI rail, and Germany Herion grinding die 2 rack, guarantee authentic so can ensure machine's stable and speed.

![]()

Print labels synchronously .

Compare with others, avoid mistakes and save time

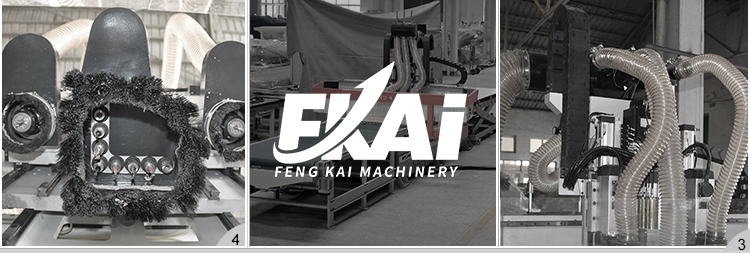

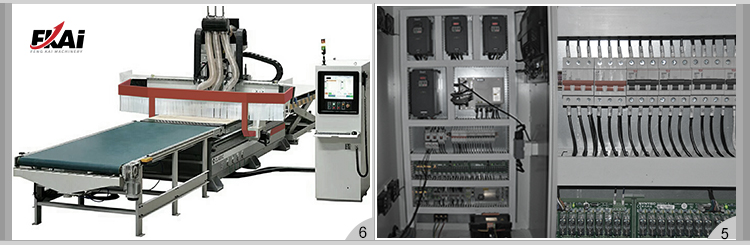

Machine body 2.Assembly and debugging 3.Dust collection 4.Main spindle Drill package

5.Electric control cabinet 6.ATC Cnc router

According to your request, custom packaging.

You only need to tell us your request, the specific operation, we will report to you in real time.

1.Operation is not very complicated, how stability?

Do not need professional carpenters, do not need skilled use of computers, staff can even take care of multiple machines work

Assembly, it’s produced by assembly engineer with over ten years experience in this industry. We use Taiwan TBI rail, and Germany Herion grinding die 2 rack, guarantee authentic so can ensure machine's stable and speed. The beam must be escrape, let the guide rail rack and machining surface fitting, each assembly by playing table method to measure accuracy, and improve stability. But many other manufactures don’t equip the beam escrape.

2.Delivery time can affect the quality?

Our workshop has 6,000 square feet,R & D department, software development department, machinery department, electrical department, the Assembly Department, after-sales commissioning, protection.235 factory workers, the annual production capacity of our factory is set to 2000 units a year standards, welcome to our factory, give us a higher guidance requirements.

3.Why I have not heard of your brand?

We have been serving the furniture factories in our country and many small export agents all along China. We started to go out and open the market ourselves.

|  |

If you have any requirement or question, please fill out the form below that we will reply you within 24 hours.