| Max. Cutting length | 3280mm |

| Mechanical arm’s running distance | 3280mm |

| Max. Height of blade | 130mm (intelligent control) |

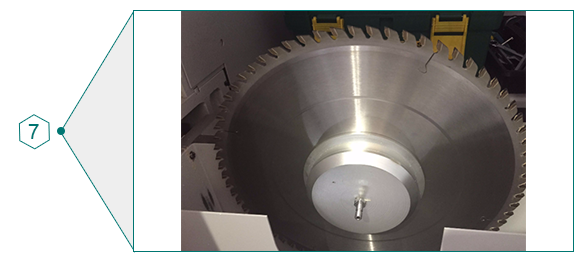

| Diameter of main saw | 400*4.4*60mm |

| Diameter of scoring sa | 160*4.4-5.4*45mm |

| Saw socket forward speed | 5-80m/min |

| Saw socket backward speed | 100m/min |

| Mechanical arm’s speed | 0-120m/min |

| Motor power of main saw shaft | 18KW |

| Motor power of scoring saw shaft | 2.2KW |

| Side pressing system | Double side pressing wheels |

| No. Of mechanical arm | 8 pcs |

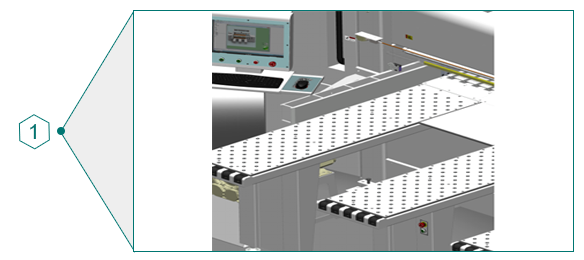

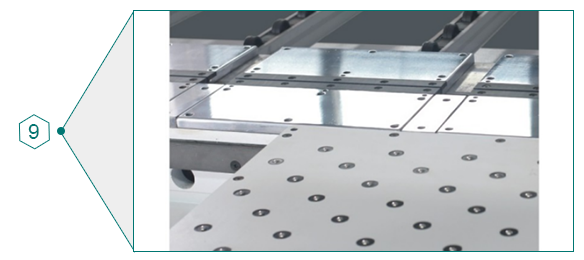

| Air bearing table | 3 pcs |

| Air compression | 6 bar |

| Air capacity | 150L/min |

| Min. Speed of dust collection | 26m/sec |

| Negative pressure (at least) | 1200 Pa |

| Input air capacity for dust collection | 4400 m3/h |

| Diameter of dust collecting holes (2 sets) | 200mm*1 |

| 150mm*1 |

1.This machine is adopt IPC control,easy to use.

2.Optimized software installation, can be directly imported material listing, optimization cutting and printing labels.

3.There is a fault alarm device,it will be stop at once when it work failure and have the function of fault automatic detection,easy to check the cause of the problem.

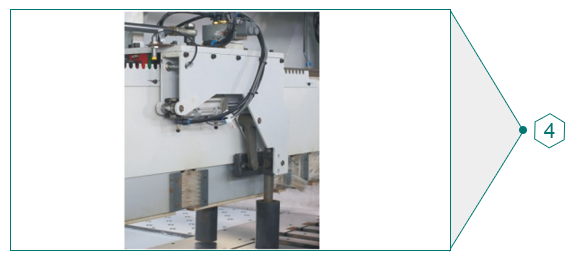

4.Conveying mechanism for reliable performance of Japan's mitsubishi AC servo motor drive, using high precision worm gear reducer, Switzerland and precision gear, rack and combination of transmission.

5.Use of electrical components and key parts and components,all adopt international famous brand products, to ensure product accuracy and reliability.

6.Main engine saw cutting is very fast,it is according to the cutting plate thickness,raelize the infinite adjustment.

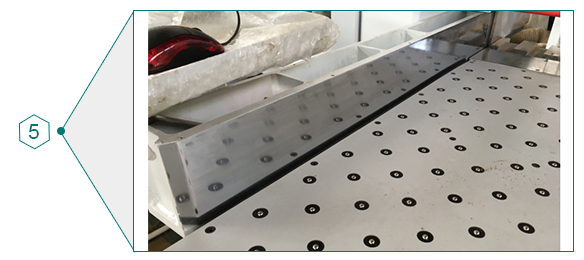

The air of 3 air floating tables are supplied from a air blower. In this way, we can move the work piece easily on the tables no matter how big it is. And there is a ON/OFF button at the side of the table.

Aluminum alloy saw carrier. Saw carrier driven by servo motor, rack & pinion, stable movement. Pull back position is automatically controlled based on next cutting length. This can reduce unused moving time and greatly improve efficiency.

control system(optional)

Double side aligner system. It fix the workpiece properly.

Chroming vertical fence is installed on the left side of machine, which is convenient for operating . And it will never get rusted.

The machine rack and working table is made of thick special steel, with steel welding vertically and horizontally. It is very stable after annealing.

Pneumatic main saw blade quick adjustment system, which helps the operator to change the saw blade easily and quickly.

The carrier rack is made up of 3 individual working devices. It pulls the main saw and scoring saw to finish the cutting process.

Resistant chroming working table protects the workpiece without damage.

Beam Panel Saw's video

Beam Panel Saw's Packaging :

1.Stretch film and plastic film for humidity.

2.Standard marine export plywood case.

3.Pallet packing.

Shipping:

1.We support maritime and land transport.

2.Shipped in 15-30 working days after payment.

Provide custom machine Yes or No?

Yes. We can provide custom machine for clients.

What's the payment terms?

T/T 30% in advance and balance before shipment or by negotiation.

How long is the warranty period?

One year warranty period except the quick-wear parts.

Do you have professional engineers?

Yes. We have professional engineers and designers

|  |

If you have any requirement or question, please fill out the form below that we will reply you within 24 hours.